Embroidery needles for perfect results

Do you occasionally have to struggle with thread breakage, "thread balls", skipped stitches, material damage, puckering or an irregular embroidery appearance? An incorrectly chosen embroidery needle could be the reason for this. We help you find the right needle for your job and give you useful tips and information so that you always achieve the best embroidery result possible.

Quick tip:

- What kind of fabric do you want to embroider (woven or knit)? This determines the type of tip to be used.

- Which thread type and count do you want to embroider with? This determines the size/diameter of the needle to be used.

The choice of needle will depend on the material being embroidered, the thread count and also the size of the design.

Needles for single and multi-head embroidery machines differ in terms of

- the needle tip

- the needle size

- the needle system (flat versus round shank geometry).

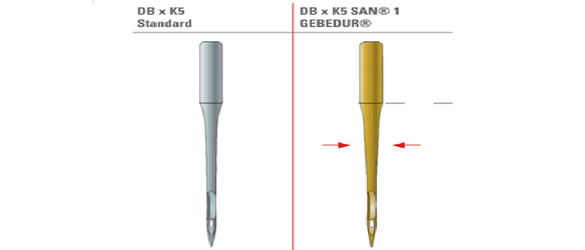

The use of a suitable embroidery needle not only reduces the amount of work and increases productivity, but can also save money. Discover high-quality, state-of-the-art embroidery needles to achieve the embroidery results you desire.

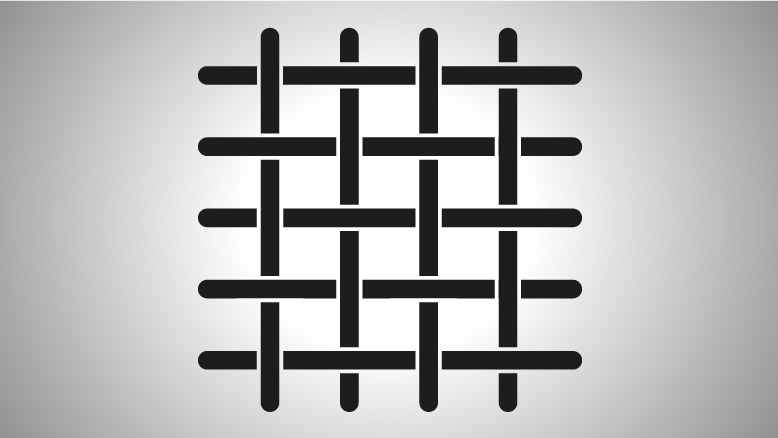

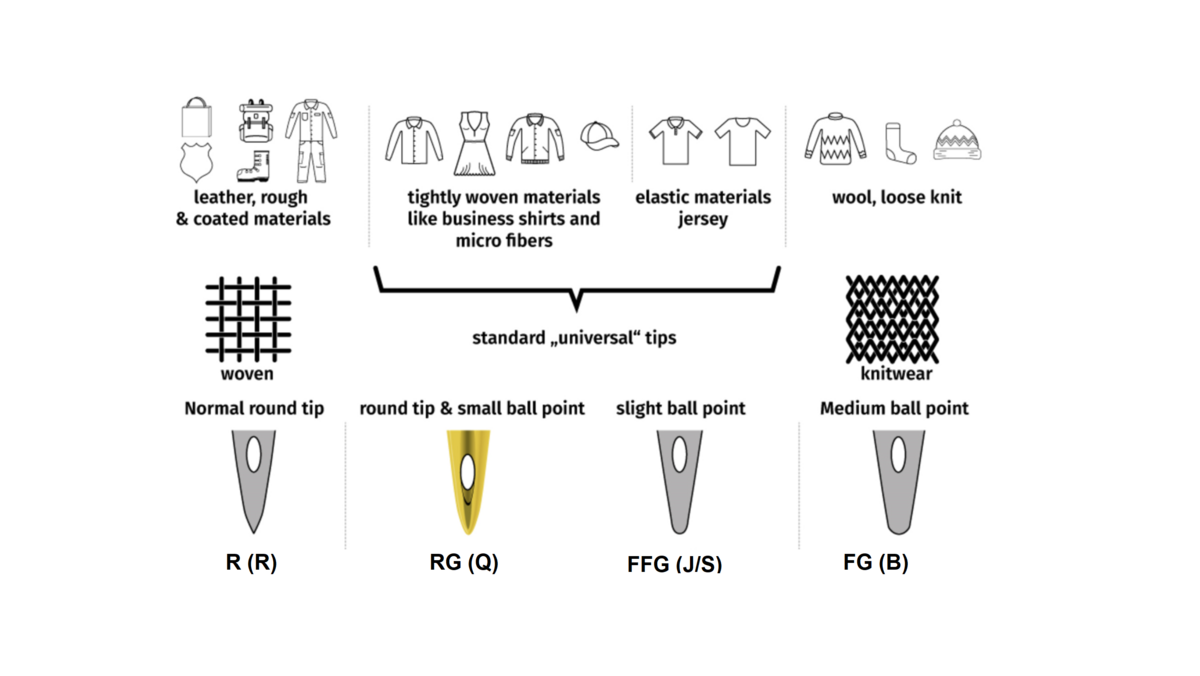

The material to be embroidered plays a decisive role in the selection of the suitable needle. With the different types of fabric, a basic distinction is made roughly between woven and knitted fabrics:

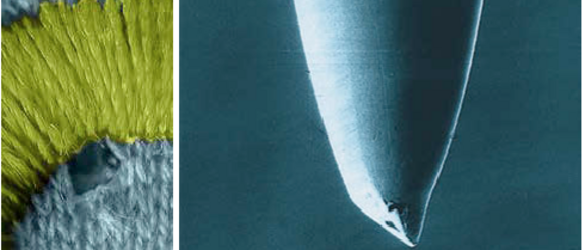

In order to protect the fabric and the embroidery design from damage, fabric threads and stitches should be displaced as far as possible when the needle is inserted.

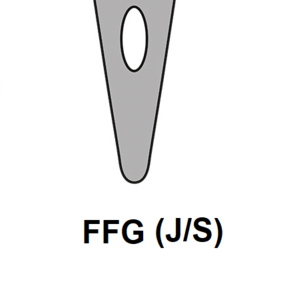

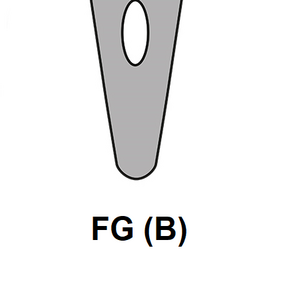

Accordingly, so-called “cloth points” are used for embroidery applications, also known as ball or round tip. They differ in their size and shape. For the sake of simplicity, we use the term "round tip" here. Round tips with a small ball displace less fabric than round tips with a large ball.

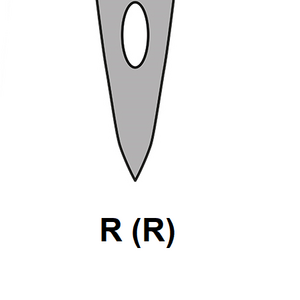

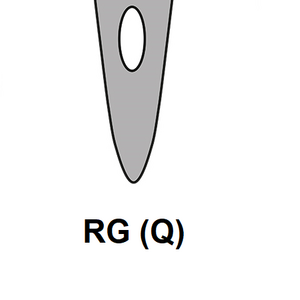

For example, if the fabric is tightly woven, the wrong needle can quickly cause waves or holes in the material. In this case, use a needle that is as “pointed” as possible, such as a round tip with a small ball (RG/Q), which can easily penetrate the fabric.

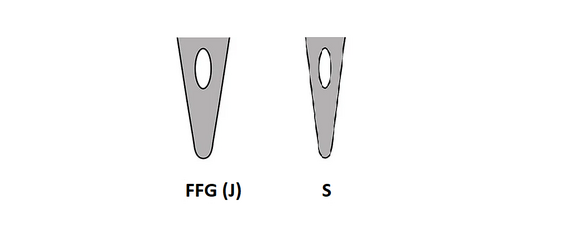

Loose, elastic woven fabrics, on the other hand, require a needle with a slightly round tip, i.e. a light / medium ball (FFG/J/S), which displaces the individual threads but does not pierce them.

A light / medium ball (FFG/J/S) should also be used for close-knit fabrics.

Coarse mesh fabric, often referred to as “knitwear” and used for cardigans or beanies, is mainly refined with patches. If you still want to apply direct embroidery, a "large round" needle or medium / large ball (FG/B) is recommended.

A rule of thumb:

The more stable and closed the surface, the smaller the round tip. The more flexible and open the surface, the larger the round tip.

Please note: Our suppliers Groz-Beckert and Organ have different tip identifications. The Groz-Beckert identification is shown outside the brackets, the Organ identification inside the brackets.

In addition to the needle tip, the needle size is decisive for the quality of the embroidery results. The size of the design, the thread and the material density determine the choice of needle size. The finer the fabric and the smaller and more detailed the motif to be embroidered, the finer the needle should be.

The information about the size on the packaging is given in two different systems: metric and singer/ Asian (American) system.

The metric system shows the size on a 1/100 scale. A needle with a needle size of 65 therefore measures 0.65 mm in diameter at its thickest point.

In the singer/ Asian (American) system, the needle is given a number based on its diameter. The higher the number, the thicker the needle.

65/9 to 75/11 needles can be used as standard needles for the majority of applications.

Download our needle selection guide now to get an overview and our recommendations on needle systems and sizes for all available Madeira threads.

The choice of needle system depends on your embroidery machine. A distinction is made between flat and round shank systems. If you are unsure which system is suitable for your embroidery machine, please contact your machine manufacturer.

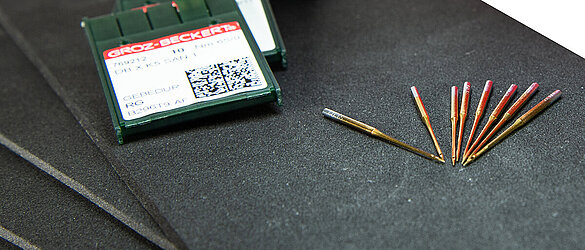

Introducing Organ needles to Madeira!

Organ has a long-standing reputation for manufacturing premium needles. At Madeira you can now find a total of six new products, among them:

- DBxK5-NY S: Round shank shank with the “S point” - narrower version of the J point - and recommended for light knitwear.

- Hax130EBBR J: Flat shank needle specifically designed for Brother PR embroidery machines (with automatic needle threader) for a flawless performance.